Aggressive chemicals

Leader Clipperlon PTFE and Elastalon seals: resistant to breakdown due to aggressive chemicals

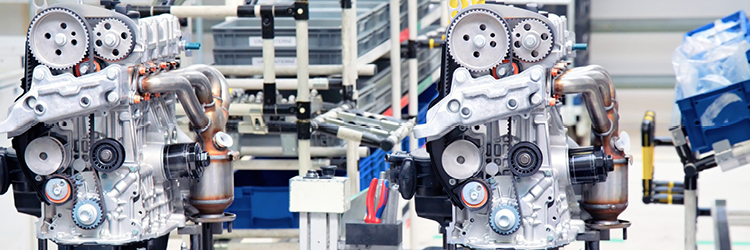

Industries such as mining, power generation, oil and chemical processing work with highly aggressive chemicals. These include acids such as hydrofluoric acid, sulfuric acid, flammable liquids, and strong bases. Leader Gasket produces special high quality gaskets which can withstand these aggressive chemicals.

Preventing leaks

Finding the right gasket is key when highly aggressive chemicals are a factor. When using standard gaskets these chemicals will or can break down the material in time. The gasket is then no longer integer and can cause leakage and cause major accicidents. Leader can assist you in ensuring you are using the right gasket for the application.

Leader Clipperlon PTFE

Leader Clipperlon PTFE seals are resistant to aggressive chemicals. In addition, they have an excellent gas-tightness and resistance to low temperatures and creep and flow. They are also suitable for use in 100% sterile environments as in the food industry or pharmaceutical industry.

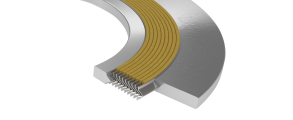

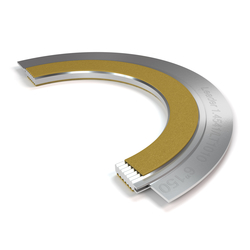

LeaderKAM

Kammprofile gaskets in both flange as Heat Exchanger construction is a unique gasket style. The metal core can be manufactured in practically all high grades of steel and alloys resistance to aggressive chemicals. This gasket style is extremely good against flange rotation. In combination with covers of (e)PTFE or high grades of Graphite or even Silver there is always the best combination of materials available covering risistance against the most aggressive chemicals.

Chemical Resistance Chart

In the interactive Chemical Resistance Chart on this website you can literally chose and compose your style of materials sufficient for your operation conditions. And the engineering teams on both continents EU and US are around the clock available to assist and support you.

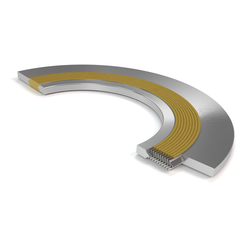

Leader Elastalon

Corrugated metal inserted ePTFE gasket. Designed to be used in application where graphite is not compatible or clean process is required. The corrugated metal substrate is commonly matched with the piping material.

Elastalon is designed specifically to solve fugitive emission and compliance problems. The chemical resistance of ePTFE is utilized due to graphite incompatibility or clean process is required.