Can we help you?

Ask us a question

Info@leadergt.com

Phone: 1-281-542-0600

Product Traceability

Traceability

Traceability is the ability to verify the history, location, or application of an item by means of documented recorded identification. Material traceability is important to the aerospace, nuclear, and process industry because they frequently make use of high strength materials that look identical to commercial low strength versions.

Leader Gasket guarantees full traceability using a heat code, job number and batch code on all manufactured products. This allows easy identification of raw materials and production settings. In case of special customer request we can provide customized product traceability, documentation and certification.

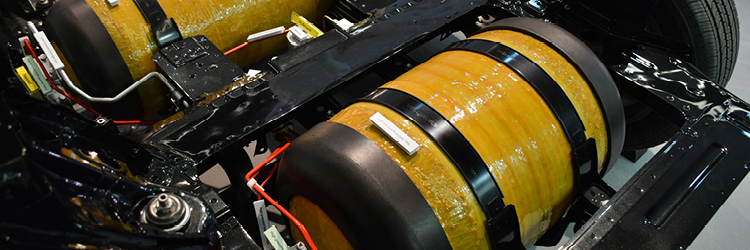

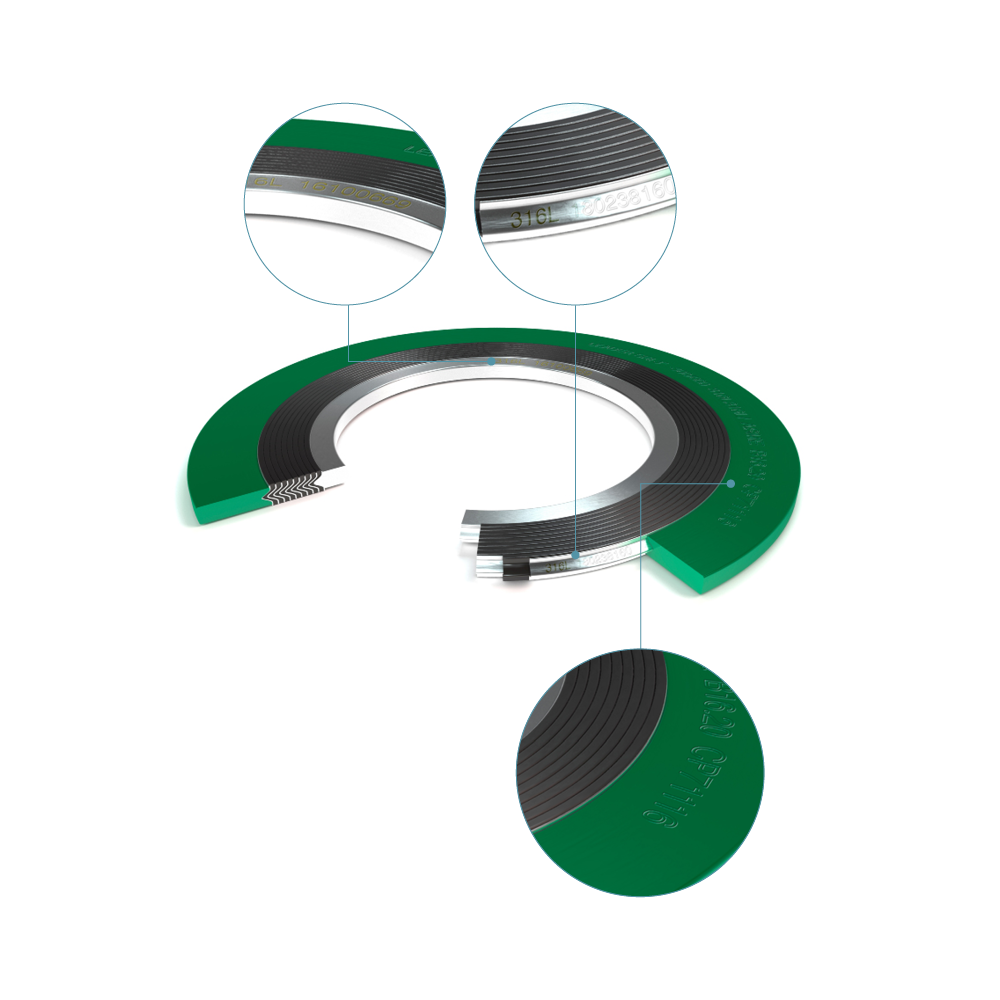

ALL METAL MATERIAL PARTS AND FILLER MATERIALS OF THE STANDARD SRI SPIRAL WOUND CONSTRUCTION ARE TRACEABLE

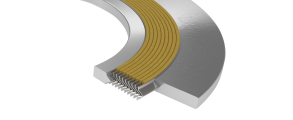

The Spiral Wound Gasket is considered to be one of the safest and most reliable of its kind but is still often seen as a commodity. Nevertheless it is a complex product containing a configuration of Windings, Fillers, Inner and Outer rings that are wound, welded and fitted together. This is how we keep control and you can sleep tight:

Highly detailed manufacturing specification requirements are in place to insure standardization, performance, and quality of each spiral wound gasket.

High performance (low emissions) graphite filler is controlled with a detailed product specification and through the use of specialized TGA testing requirements for each lot of graphite material used. In process inspections by qualified inspectors in accordance with ASME B16.20 standards are performed and documented on every shipment.

Leader Gasket in-house quick supply special gaskets are manufactured to the same stringent specification requirements.

Traceability is achieved through detailed MTR (material test reports and certificates) documentation for inner/outer rings, metal windings, and graphite filler.

All metal material parts and filler materials of the standard SRI Spiral Woulnd construction are traceable for each gasket by use of a unique traceable number (batchcode) marked on the inner/outer guide rings along with the etching of the metal winding material.

Standard 304 & 316ss SR/SRI guide rings are painted on the face with the matching ASME color code (Green for 316 & Yellow for 304ss) for a quick visual reference when stocking.