Fugitive emissions

Specialists in reducing fugitive emissions by presenting sustainable gasket solutions

Leaks can cause the emission of gases and vapors in pressurized industrial equipment. Losing raw materials is not only problematic because of costs. This loss also creates a multitude of risks and dangers. In the long term, certain chemicals may pose a risk to the health of workers. A leak of flammable substances increases the risk of fire and explosion. In addition, the emission of chemical substances is harmful to the environment.

Emission reduction

Seals and connections are the greatest risk to potential leakage points. In large industrial installations there are many gaskets present and when these gaskets are not reliable, total emission can soar. Leader Gasket is specialized in gaskets that reduce fugitive emissions. Through education about the proper gasket selection, proper calculations and installation advice, Leader can help any industry with emission reduction.

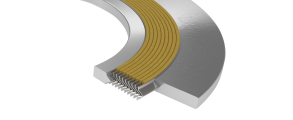

Leader Elastagraph

Leader Elastagraph™ gaskets are produced by infusing seamless layers of flexible graphite at varying densities and thicknesses over a corrugated metallic core. Elastagraph™ utilizes a unique corrugated pattern which increases the depth of the groove and the pitch at the peak of the corrugation. This greatly improves the gaskets sealability over traditional corrugated designs.

Even at low seating stresses Leader Elastagraph gaskets are showing very low leakage rates and so contributes to reduce emissions in flange constructions to a minimum.

Leader Clipperlon

In the Leader Clipperlon biaxial orientated modified PTFE range Style 2110 blue has very good adaptability against on all flange materials and roughness’s up to glass or ceramic lines and plastic flanges. Due to the low seating stress needed, low leakages are achieved under normal to most extreme circumstances. Leader Clipperlon 2110 is inert and has a high chemical resistance; therefore Leader Clipperlon can be seen as most tight modified PTFE gasket in its range