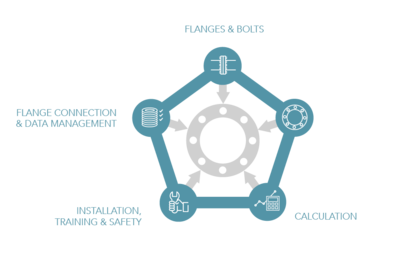

Total Flange Care

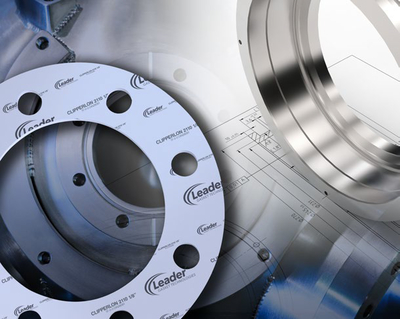

There are many parameters which impact the performance of a gasket. Identifying these factors and ensuring they are all optimized to provide you with a safe and sustainable flange connection is at the core of our business. At Leader Gasket we call this approach Total Flange Care.

Innovation

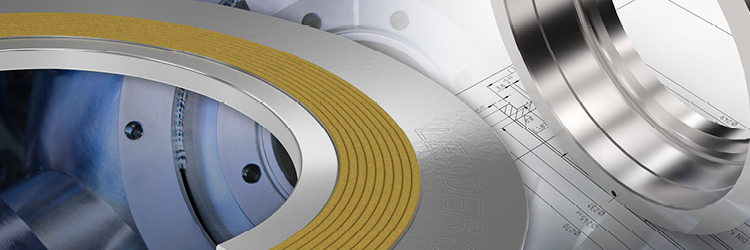

The development of gaskets is a process that is always in motion. At Leader Gasket we operate in the forefront of this field. Our engineering team utilizes the latest techniques to develop innovative gaskets, specifically designed to perform optimally in increasingly complicated processes in various industries.

Gasket failure?

A leaking flange connection is often called a “gasket failure”. Yet, in many cases simply replacing the gasket doesn’t solve the problem. This is because there are many factors which have a direct and indirect impact on the performance of a flange connection. The gasket itself is a very important part of the equation, but it can only perform as intended when it is properly installed and maintained.

Flange Integrity management

This why we call a leaking flange connection an “integrity problem”. Our approach to solving this problem is Flange Integrity Management. This is where we systematically identify all the contributing factors that cause the leak and establish the right approach to come up with a lasting solution.

Four parameters

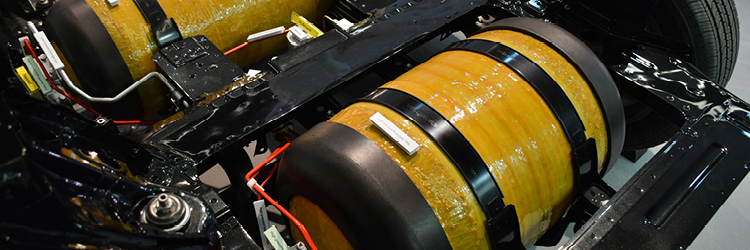

Safety and sustainability are the highest concern in industrial gasketting. Creating and maintaining a leak free flange connections is of the utmost importance. At Leader Gasket we always look at the combination of the following four parameters:

- Gasket

- Flanges and bolts

- Assembly

- Operating conditions

MEETING THE HIGHEST STANDARD!

Training mechanics / engineers EN1591-4

Advising gasket selection

Inspection and recommendation flange parameters

Gasket testing

Calculation bolt force, tightness and emission

Flange management programs

LDAR