Petrochemical Industry, Steam, On- and Offshore exploration, pipeline systems, pressure vessels and exchangers.

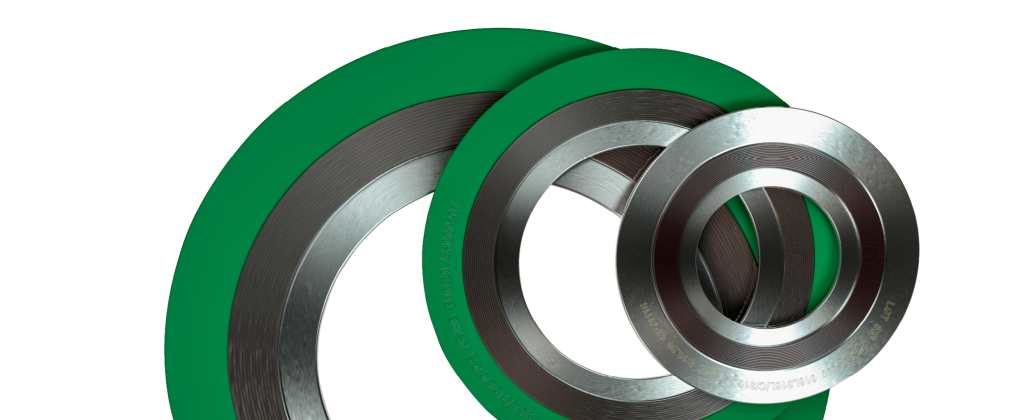

Spiral Wound Gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application/ compatibility guide is available on request. Temperature from –450 °F up to 850 °F (steam up to 1200 °F)

Standard gaskets are manufactured according EN1514-2 for EN/DIN-flanges class PN10 – PN400 and ASME B16.20 / EN 12560-2, for flanges acc. ASME B16.5 class 150-2500 Class.