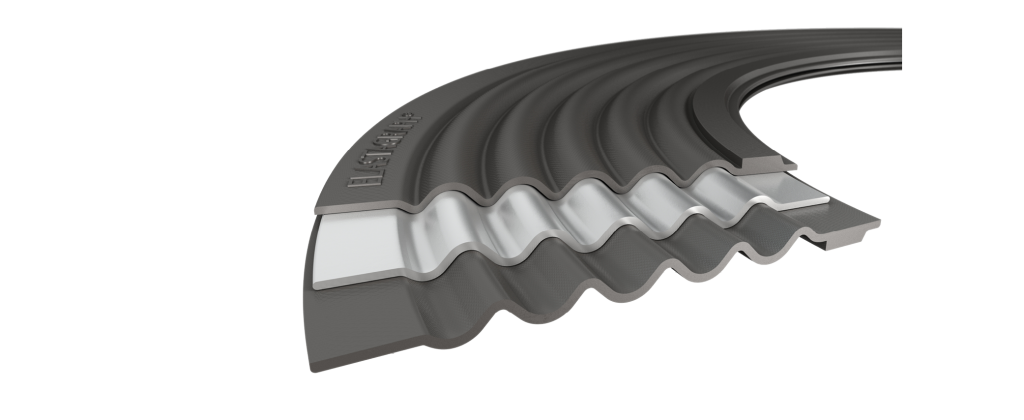

Elastagraph DS gaskets are produced by adding a layer of graphite over a corrugated metal core. Then ePTFE is applied to the I.D. portion of the corrugated core with an 1/8” overlap. Elastagraph DS utilizes a unique corrugated pattern which increases the depth of the groove and the pitch at the peak of the corrugation. This greatly improves the gaskets sealability over traditional corrugated designs.

Elastagraph DS is designed specifically to solve fugitive emission and compliance problems. Combines the chemical resistance of ePTFE and graphite that is fire safe. It also has excellent performance in bolted joints that experience thermal cycling or limited initial bolt load.

Combines the chemical resistance of ePTFE and graphite that is fire safe.

Elastagraph DS flange gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application / compatibility guide is available on request. Pressure from vacuum to ASME class 600 and DIN/EN class PN40. Temperature from -400 ºF to 850 ºF (steam 1200 ºF).

Standard gaskets are available in accordance with ASME B16.21 (1/2” – 24”) , EN12560-1 as well as EN1514-1 (DN10- DN600). Standard thickness is 1,6 mm (1/16”) 3,2 mm (1/8”).Non-standard, or special gaskets, can be manufactured according to customer drawings, or by given sizes. Please note that tooling may be required.

Temperature from -400 ºF to 850 ºF (steam 1200 ºF).