Can we help you?

Ask us a question

Info@leadergt.com

Phone: 1-281-542-0600

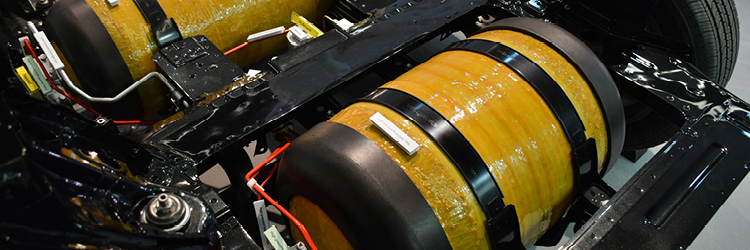

Refineries

We deliver reliable quality and safety for your installation

Leader Gasket has been at home in the world refineries for over 100 years. In close cooperation with our allied distributors have extensive experience in making products that can withstand the demands of high pressure, cracking plants, hazardous materials and gases, high temperatures and critical processes. This makes Leader Gasket a reliable supplier and service provider for a great number of refineries around the globe; listed on many AML’s (Approved Manufacturer List) that we can provide you on request

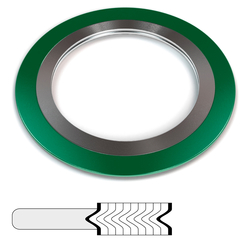

Leader SR & SRI

Spiral wound gaskets are still the most popular and highest integrity choice in refineries due to the wide variety of available styles and sizes. They can be manufactured of any metal raw materials which is available in thin strip and which can be welded. Filler materials graphite ePTFE and LeaderTHERM mica can provide solutions for adequate sealing against all media. For this industry Leader uses HDLE (High density Low Emission) high grade inhabited graphite as filler ensuring low emission and high integrity.

Leader Spiral Wound gaskets ensure high safety levels in flange gaskets used at major customers in Refining Industry

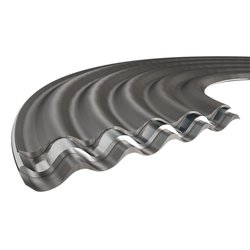

Leader Elastagraph

Leader Elastagraph™ gaskets are produced by infusing seamless layers of flexible graphite at varying densities and thicknesses over a corrugated metallic core. Elastagraph™ utilizes a unique corrugated pattern which increases the depth of the groove and the pitch at the peak of the corrugation. This greatly improves the gaskets sealability over traditional corrugated designs.

Even at low seating stresses Leader Elastagraph gaskets are showing very low leakage rates and so contributes to reduce emissions in flange constructions to a minimum.

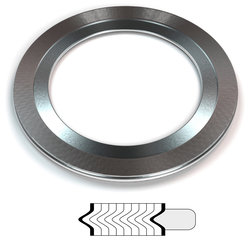

Leader Corrugated Metal Graphite Gaskets

The corrugated is designed for high performance standard flange gaskets or heat exchanger applications. Designed as an engineered solution for large diameter fixed equipment where leakage and low available loads are issues.

High performance replacement for asbestos, jacketed gaskets, spiral wounds is a less expensive option as compared to a Kammprofile gasket.

Leader SRI-LCP & SRI-LCG

These gaskets are designed for Alkaline services. It is a severe service fluid sealing technology product that is designed to eliminate crevice corrosion at ID of flanges. This product is used for application in HF Acid and other hazardous service requirements.

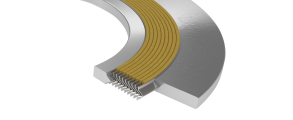

LeaderKam

This Kammprofile Gasket is highly recognized as the problem solver for heat exchangers, large vessels and units that see excessive movement from thermal expansion. The Kammprofile provides the tightest seal combined with superior load bearing characteristics. This gasket design is made with a metal core and available with or without outer ring. The metal core with its concentric serrations can be faced with graphite, ePTFE or Leader Therm.

Leader RTJ

Leader Ring Joint gaskets are developed for use in the petroleum industry and in particular for wellhead and Christmas tree- as well as drilling and oil & gas production equipment.

These solid precision machined metallic gaskets, also called and known as ring type joint (RTJ) gaskets are suitable for the highest possible pressure and temperature duties and form together with special grooved API 6A (ISO 10423) type 6BX flanges a high integrity seal.

LeaderRTJ gaskets are manufactured in strict accordance with API 6A (ISO 10423)

EN10.204 3.1 or 3.2 certification can be delivered on request, as well as NACE MR0175/ISO 15156 conformity statement.

Leader Jacketed Gaskets

Typically supplied with a non-asbestos, high temperature filler. The standard filler is normally sufficient for applications up to 900° F. Standard metals used to make jacketed gaskets are carbon steel, aluminum, copper, brass, nickel, Monel, Inconel and stainless steel 304, 316, 321, 347 & 410.