Can we help you?

Ask us a question

Info@leadergt.com

Phone: 1-281-542-0600

CHEMICAL

Reliable supplier in demanding environment

Workplaces and sites within the chemical industry are subject to strict regulations regarding safety and environmental requirements. Leader Gasket has knowledge and experience in the field of maintenance, midstream activities, system monitoring and on-site testing in this industry. As a manufacturer and supplier we are engaged in major projects of international contractors in this field. Leaders Flange Integrity Management program contributes in the Chemical Industry to higher levels of safety, integrity and emission reduction.

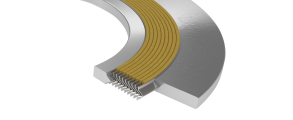

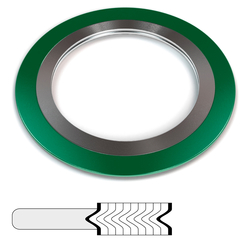

Leader SR & SRI

Spiral wound gaskets are still the most popular, reliable and higher integrity gaskets used in mid to high class pressure system due to the wide variety of styles and sizes available with and without inner rings. They can be fabricated out of any metal materials which is available in thin strip and which can be welded; therefore, they can be used against virtually any corrosive medium dependent upon the choice of metal and fillers such as High Performance Low Emission flexible Graphite (HPLE) and e PTFE sintered or un-sintered.

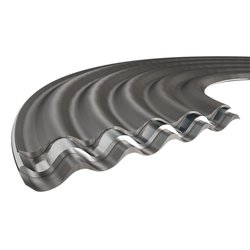

Leader Corrugated Metal Graphite Gaskets

The corrugated gasket Elastagraph® designed for high performance, blow out resistant, gaskets for standard flange or heat exchanger applications for low emissions. Designed as an engineered solution for large diameter fixed equipment and units that see excessive movement from thermal expansion and where leakage and low available load are issues. High performance replacement for asbestos, jacketed gaskets, spiral wounds and is a less expensive option as compared to a Kammprofile gasket.

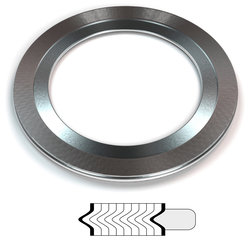

LeaderKAM

This Kammprofile Gasket is highly recognized as the problem solver for Heat Exchangers, Large Vessels. The Kammprofile provides the tightest seal combined with superior load bearing characteristics. This gasket design is made with a metal core and available with or without outer ring. The metal core with its concentric serrations can be faced with graphite, ePTFE or LeaderTHERM.

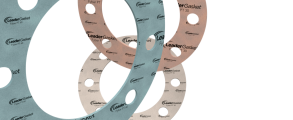

Leader Clipperlon modified PTFE

Leader Gasket’s Clipperlon range of modified PTFE sheet gasket are resistant to a broad range aggressive chemicals. In addition, they have an excellent gas-tightness and resistance to low temperatures and creep and flow. Clipperlon sheet gaskets are easy to handle and to be cut by hand in emergency cases. Some Clipperlon styles are also suitable for use in 100% sterile environments as in the food industry or pharmaceutical industry. For low to middle pressure systems Clipperlon is a universal pipe gasket in Chemical Industy.