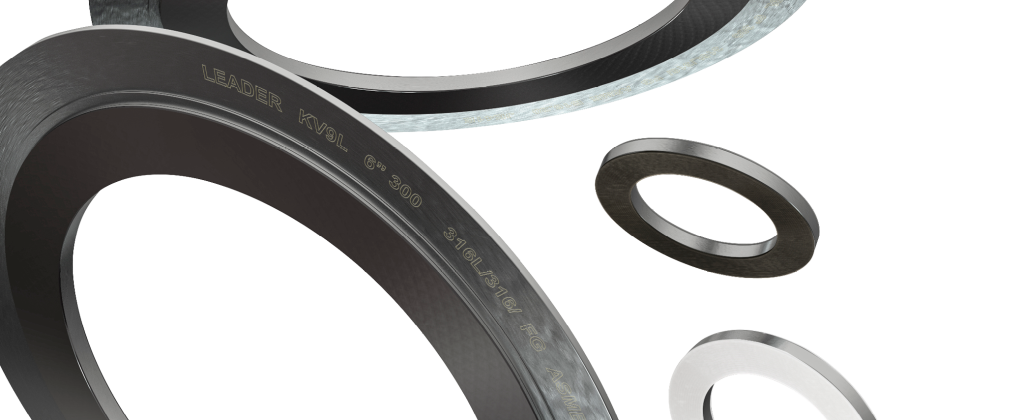

Petrochemical Industry, Steam, On- and Offshore exploration, pipeline systems, pressure vessels, heat exchangers and coolers. LeaderKAM Kamprofile gaskets have proven records in demanding application with heat-exchangers with fluctuating and cycling process conditions. Superb alternative for metal jacketed gaskets.

They are capable of handling low load applications and very high demanding load services.

LeaderKAM kammprofile Gaskets are suited for a wide variety of media, e.g. a pH range varying from 0-14. Temperature range from –450 °F up to 850 degrees °F (steam 1200 °F) with graphite layers. Leadertherm Mica layers can withstand temperatures of 1800 °F.

All dimensions in a wide variety of materials are possible. Available for standard and non-standard equipment gaskets. Certificates can be delivered on request.

Temperature range from –450 °F up to 850 degrees °F (steam 1200 °F) with graphite layers. LeaderTHERM (phlogopite) layers can withstand temperatures of 1800 °F. Application/ compatibility guide is available on request.

Contact

Leader Gasket

Global Headquarters: Houston, TX

850 Sens Road

La Porte, TX 77571

Contact Us

Phone: +1 281-542-0600