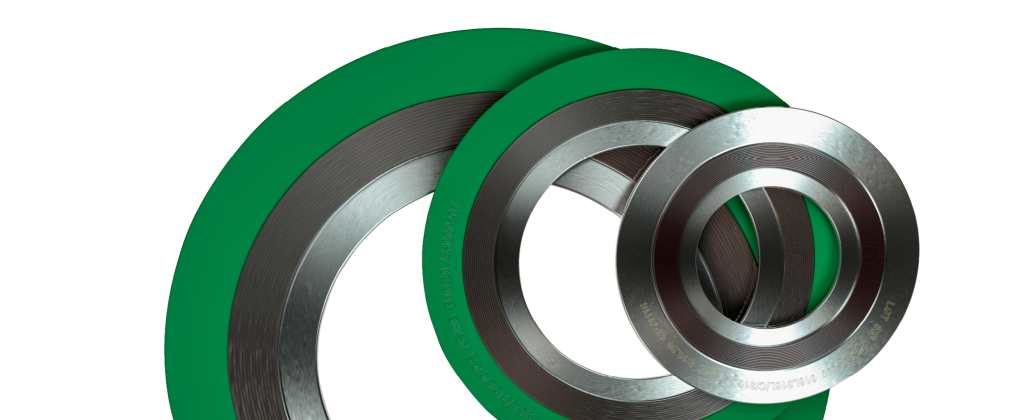

SpiralKAM SRI-LCP and SRI-LCG: Two Seals, One Design. Advanced fluid sealing technology for severe service applications, engineered to prevent crevice corrosion at flange IDs. It is ideal for use in HF acid and other hazardous environments. Constructed from alloy materials tailored to

the process media and corrosive conditions. The primary seal features a LeaderKAM kammprofile with an PTFE coated or alloy construction, while the secondary seal incorporates a spiral wound with inhibited grade high purity graphite or ePTFE.

Petrochemical Industry, Steam, On and Off shore Exploration, Pipeline Systems, Pressure Vessels, Exchanges, and Alkylation units.

Subject to materials, Leader SpiralKAM can be used in a wide variety of media, with a pH range varying from 0-14. Application/Compatibility Guide is available on request.

Standard gaskets are manufactured according EN1514-2 for EN/DIN-flanges class PN10 – PN400 and ASME B16.20 / EN 12560-2, for flanges acc. ASME B16.5 class 150-2500lbs. Also, non-standard equipment gaskets can be manufactured up to a diameter of 4000 mm. We have a large stock in Carbon Steel and SS316L. Other materials are also available.

Contact

Leader Gasket

Global Headquarters: Houston, TX

850 Sens Road

La Porte, TX 77571

Contact Us

Phone: +1 281-542-0600