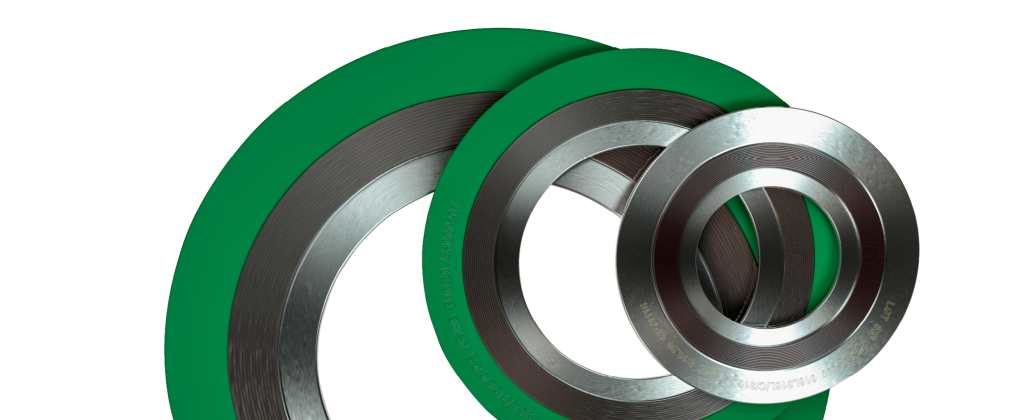

Designed more than 100 years ago, Spiral Wound Gaskets are widely used as high-integrity and sustainable gaskets. The sealing element is manufactured from preformed, shaped metallic windings with intermediate soft sealing fillers. The standard metallic material used for winding and the inner ring is SS316L, while the soft fi ller consists of graphite, PTFE, or LeaderTherm NXT 1000 (a high-temperature modified Phlogopite). Due to the gasket’s construction, SWGs off er high compressibility and recovery. Leader Style SI SWGs are provided with an inner ring. The SI gaskets are suitable for ASME B16.5 tongue and groove or male/female (Spigot to Recess) flanges

Petrochemical Industry, Steam, On and Off shore Exploration, Pipeline Systems, Pressure Vessels, and Exchangers.

Subject to materials, Spiral Wound Gaskets can be used in a wide variety of media, with a pH range varying from 0-14. Application/Compatibility Guide is available on request.

Standard style SI gaskets are normally manufactured according to customer drawings, or by given sizes. Gaskets can be manufactured in a thickness of .125″ / .175″ / .250″ / 285″.

Contact

Leader Gasket

Global Headquarters: Houston, TX

850 Sens Road

La Porte, TX 77571

Contact Us

Phone: +1 281-542-0600