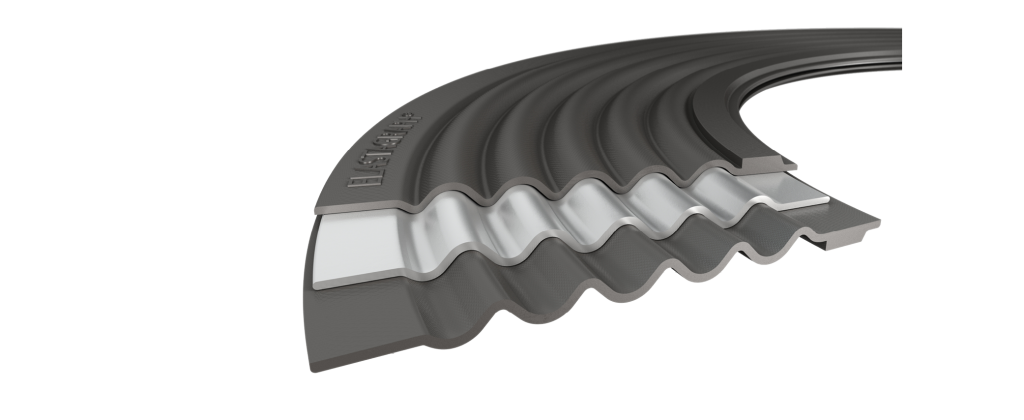

Elastagraph™ gaskets are produced by adding a layer of graphite over a corrugated metal core. Elastagraph™ utilizes a unique corrugated pattern which increases the depth of the groove and the pitch at the peak of the corrugation. This greatly improves the gaskets sealability over traditional corrugated designs.

Elastagraph™ is designed specifically to solve fugitive emission and compliance problems. It also has excellent performance in bolted joints that experience thermal cycling or limited initial bolt load. Elastagraph™ is the cost effective way of meeting low emission requirements.

Excellent sealing against vaporous and media like gases and thermal (hot) oil.

Elastagraph™ flange gaskets can be used in a wide variety of media, i.e. a pH range varying from 0-14. Application / compatibility guide is available on request. Pressure from vacuum to ASME class 300 and DIN/EN class PN40. Consult with Engineering for pressure classes above 300.

Standard gaskets are available in accordance with ASME B16.21 (1/2” – 24”) , EN12560-1 as well as EN1514-1 (DN10- DN600). Standard thickness is 1,6 mm (1/16”) 3,2 mm (1/8”).Non-standard, or special gaskets, can be manufactured according to particular customer drawings, or by given sizes. Please note that tooling may be required. We have a large stock in SS316L. Other materials are also available.

Temperature from -400 ºF to 850 ºF (steam 1200 ºF). Dependent on material construction. Consult with Engineering for specific application.