Can we help you?

Ask us a question

Info@leadergt.com

Phone: 1-281-542-0600

Glossary

- Allowable stress

The maximum stress a designer can assume that the parts will stand. Is always less than the minimum strength of the material. For example, the ASME Boiler and Pressure Vessel Code typically specifies an allowable stress that is one-quarter of the service temperature yield strength of the material. This introduces a four-to-one safety factor into the design process and is intended to compensate for uncertainties in estimates of strength, service loads, etc.

- Allowable stress design

A design procedure developed for the AISC by the Research Council on Structural Connections. Purposely underestimates the strengths of bolts and joint materials to introduce safety factors into the design of structural steel joints. Is an alternative to the more recently defined load and resistance factor design procedure.

- Anode

That electrode in a battery or corrosi on cell which produces electrons. It is the electrode which is destroyed (corrodes).

- ASME

The American Society of Mechanical Engineers.

- Assembly pressurePressure generated on a gasket during assembly.

- Beater addition product

Gasket material manufactured by a paper-making process.

- Belleville washer

Washer with a slightly conical shape, which acts as a spring

when compressed axially. - Binder

A substance (usually organic) used to bond the components of a

gasket material into a matrix. - Boiler and Pressure Vessel Code

A large and complex document maintained and published by the American Society of Mechanical Engineers (ASME). The

code describes design rules, material properties, inspection techniques, fabrication vessels. The recommendations of the

Code have been adopted by most states, and have influenced similar Codes in many countries.techniques, etc., for boilers

and pressure - Bolt

Officially, a threaded fastener designed to be used with a nut. The word is often used interchangeably with Threaded fastener

for convenience. - Brittle

A bolt is said to be brittle if it will break when stretched only a small amount past its yield point.

- Cathode

That electrode in a battery or corrosion cell which attracts electrons.

- Centering ring

An extension of a gasket for the purpose of locating it centrally on a flange.

- Clamping force

The equal and opposite forces which exist at the interface between two joint members. The clamping force is created by

tightening the bolts, but is not always equal to the combined tension in the bolts. Hole interference problems, for example,

can create a difference between clamping force and bolt loads. - Compressed fiber sheet

Gasket material, primarily containing fibers, rubber and fillers, manufactured on a calendar under high load.

- Compressibility

Percentage reduction of thickness under a compressive pressure, applied at a constant rate, at room temperature.

- Compression set

Residual deformation of a gasket after it has been subjected to, and then released from a specified compressive pressure, over a defined time and at a given temperature.

- Controlled swell

Property of gasket material to swell to a defined extent when in contact with the retained fluid, to provide additional sealing

pressure. - Corrosion cell

A natural “battery” formed when two metals having different electrical potentials (an Anode and a Cathode) are connected together in the presence of a liquid (the Electrolyte).

- Corrugated metallic gasket

Metal gasket usually incorporating a filler material in the well of the corrugations, in which the seal is formed between the peaks of the corrugations and the mating flanges.

- Creep

The slow, plastic deformation of a body under heavy loads. Time-dependent plasticity.

- Creep deformation

Percentage loss of thickness over a specified time under constant load, applied at a specified rate, at a specified temperature.

- Cure

Cross-linking reaction of elastomer with various chemicals, creating a matrix of greater stability.

- Double-jacketed gasket

A gasket design in which the gasket material is enclosed within an outer metal cover.

- Ductile

If a bolt can be stretched well past its yield point before breaking it is said to be ductile. (See also brittle)

- Eccentric load

The external load on a fastener or groups of fasteners is said to be eccentric if the resultant of that load does not pass through the centroid of the group of fasteners (eccentric shear load) or does not coincide with the bolt axis (eccentric tensile load).

- Effective length of a bolt

The grip length plus some portion of the bolt (often one-half of the thickness of the nuts) which lies within the nut(s) plus some portion (often one-half the thickness) of the head. Used in stiffness and stretch calculations.

- Effective radius of nut, or bolt head, or threads

Distance between the geometric center of the part and the circle of points through which the resultant contact forces between mating parts passes. Must be determined by integration.

- Effective sealing width

That part of the actual width of a gasket considered to contribute to the performance of the gasket.

- Elastic interactions

When a bolt is tightened it partially compresses the joint members “in its own neighborhood.” When nearby bolts are tightened later, they further compress the joint in this region. This allows the first bolt to relax a little (lose a little preload). Tightening bolts on the opposite side of the joint, however, might INCREASE preload in some of the earlier bolts tightened on the near side. These shifts and changes in the elastic energy stored in individual bolts, during assembly, are called elastic interactions.

- Elasticity

Property of a body to recover its original size and shape immediately after removal of the external forces which cause it to deform.

- Elastomer

Generally long chain polymer molecules, which show elastic properties.

- Electrode

The two metallic bodies in a battery or Corrosion cell which give up electrons (the Anode) or which attract them (the Cathode).

- Electrolyte

The liquid with which the Electrodes of a battery or Corrosion cell are wetted.

- Embedment

Localized plastic deformation in heavily loaded fasteners allows one part to sink into, or smooth the surface of, a softer or more heavily loaded second part. Nuts embed themselves in joint surfaces. Bolt threads embed themselves in nut threads, etc.

- Endurance limit

That completely reversing stress limit below which a bolt or joint member will have an essentially infinite life under cyclic fatigue loads. Note that the mean stress on the bolts here is zero.

- Envelope gasket

A gasket design in which the gasket material is enclosed within an outer cover (typically PTFE) to minimize chemical degradation by the sealed fluid.

- Extensometer

Any instrument which measures the change in length of a part as the part is loaded.

- External load

Forces exerted on fastener and/or joint members by such external factors as weight, wind, inertia, vibration, temperature expansion, pressure, etc. Does not equal the Working load in the fastener.

- Eyelet

Metallic cover around inner periphery of gasket material, to minimize chemical degradation by the sealed fluid. Depending on selection of geometry and metal, it may also improve sealability and blowout resistance.

- Failure of the bolt

Term implying that the bolt has broken or the threads have stripped. There can be many reasons for this.

- Failure of the joint

Failure of a bolted joint to behave as intended by the designer. Failure can be caused or accompanied by broken or lost bolts, but can also mean joint slip or leakage from a gasketed joint even if all bolts still remain whole and in place. Common reasons for joint failure include vibration loosening, poor assembly practices, improper design, unexpected service loads or conditions, etc.

- Flange

Basic component of a gasketed joint assembly, incorporating a substantially radially extending collar for the purpose of joining two or more items of process equipment.

- Flange rotation

Deformation of a flange caused by imposed forces.

- Flat-face flange

A flange where the entire mating faces are flat.

- Fluid resistance

Measure of the ability of the material to resist chemical attack.

- Fugitive emission

A chemical or mixture of chemicals, in any physical form, which represents an unanticipated leak, from anywhere on an industrial site.

- Full-face gasket

A gasket which covers the entire flange surface extending beyond the bolt holes.

Galling

An extreme form of adhesive wear, in which large chunks of one part stick to the mating part (during sliding contact).

Galvanic protection

The coating on a fastener is said to provide galvanic protection if it is more anodic than the fastener and will, therefore, be destroyed instead of the fastener. Zinc plate (galvanizing) provides galvanic protection to steel fasteners, for example.

Gasket

Deformable material (or combination of materials) intended to be clamped between flanges to prevent leakage of contained fluid.

Gasket factors

Experimentally derived “constants” used to define the behavior of a gasket and/or the assembly and in-service conditions required for acceptable behavior. The term “gasket factor” comes from the Boiler and Pressure Vessel Code, which contains tabulation of m and y factors defining the recommended Gasket stress in-service and at assembly-for design purposes only. (Actual assembly and in-service stresses will usually be greater.) New factors, called Gb, a, and Gs, have recently been proposed for the Code. These factors are not design recommendations, but instead, define the behavior of the gasket.

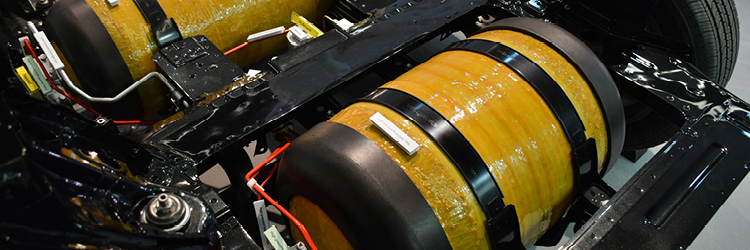

Gasketed joint

The assembly of components (e.g. flanges, bolts, gaskets) required to join two or more items of process equipment and to prevent leakage.

Gasket load reaction

Point at which the load on a gasket can be considered to react for moment calculation purposes.

Gasket pressure

Effective compressive load per unit of gasket area.

Gasket stress

The contact stress exerted on the gasket by the joint members.

Grip length

Combined thickness of all the things clamped together by the bolt and nut, including washers, gaskets, and joint members.

- Hard and soft gasket materials

Differentiation between predominantly hard, metal-based gasket (e.g. spiral wound) and softer or fibre-reinforced materials.

- Hot creep during service

Percentage reduction in thickness under constant compressive pressure at elevated temperature.

- Hydrostatic end thrust

Relieving force caused by the pressure of the retained fluid, resulting in a reduction in gasket pressure and an increase in bolt load.

- Impact wrench

An air-or electric-powered wrench in which multiple blows from tiny hammers are used to produce output torque to tighten fasteners.

- Initial preload

The tension created in a single bolt as it is tightened. Will usually be modified by subsequent assembly operations (see Elastic interactions) and/or by in-service loads and conditions.

- Inside bolt circle (IBC) gasket

A gasket lying wholly within a ring of bolts.

- Internal pressure

Fluid pressure applied to the joint.

- Kammprofile gasket

Metal gasket with grooved faces, with or without resilient sealing layer on surfaces.

- Leakage rate

Quantity of fluid passing through the body and/or over the faces of a gasket per unit periphery of the gasket over a specified time.

- Live loading

Application of a spring load to maintain seal surface pressure.

- Material velocity

The velocity of sound in a body (e.g., a bolt). A term used in the ultrasonic measurement of bolt stress or strain.

- Mean value

The average value of a number of data points. Computed by dividing the sum of all data by the number of data points.

- Nominal diameter

The “catalog diameter” of a fastener. Usually roughly equal to the diameter of the body, or the outer diameter of the threads.

- Nut factor

An experimental constant used to evaluate or describe the ratio between the torque applied to a fastener and the Preload achieved as a result.

- Permeability

A measure of the ease with which a fluid can pass through a gasket material.

- Pitch

The nominal distance between two adjacent thread roots or crests.

- Preload

The tension created in a threaded fastener when the nut is first tightened. Often used interchangeably, but incorrectly, with working load, bolt force or bolt tension.

- Preload accuracy

A measure of the precision with which a given tool or procedure creates preload in a bolt when the bolt is tightened. A common torque wrench, for example, is said to produce preload with an accuracy of +30%. The mean preload, however, may not be that which the designer intended, or may not be what he should have intended. Accuracy as used here, in other words, is synonymous with Scatter.

- Prevailing torque

Torque required to run a nut down against the joint when some obstruction, such as a plastic insert in the threads, or a noncircular thread, or other, has been introduced to help the fastener resist vibration loosening. Prevailing torque, unlike

“normal” torque on a nut or bolt, is not proportional to the Preload in the fastener. - Proof load

The maximum, safe, static, tensile load which can be placed on a fastener without yielding it. Sometimes given as a force (in lb or N) sometimes as a stress (in psi or MPa).

- PT value

Numerical value resulting from the multiplication of the internal pressure by the temperature of the fluid being sealed. Provides only a rough guide for limiting gasket usage.

- PVRC

Pressure vessel research committee (USA)

- Raised-face flange

A flange which makes contact with its mating joint member only in the region where the gasket is located. The faces of the flange do not make contact with each other at the bolt circle.

- Recovery

Increase of thickness over the compressed thickness, once the compressive load has been removed

- Reinforcement

Material (such as fabric, cord and/or metal) within the gasket matrix, which imparts increased tensile strength or other desirable properties.

- Relaxation

The loss of tension, and therefore Clamping force, in a bolt and joint as a result of Embedment, vibration loosening, gasket creep, differential thermal expansion, etc.

- Residual preload

The tension which remains in an unloaded bolted joint after Relaxation.

- Residual stress

Stress remaining in a gasket after service for a given time.

- Ring-joint flange

A flange system in which both flanges are grooved to accept a ring-joint gasket

- Ring-joint gasket

A gasket machined from metal (usually oval or octagonal in cross-section) and used in conjunction with ring-joint flanges.

- Rolled thread

A thread formed by plastically deforming the surface of the blank rather than by cutting operations. Increases fatigue life and thread strength, but is not possible (or perhaps economical) on larger sizes.

- ROTT

Room temperature operational tightness test, as defined by the PVRC.

- Scatter

Data points or calculations are said to be scattered when they are not all the same. A “lot of scatter in preload” means wide variation in the preloads found in individual bolts.

- Sealability

Ability of a gasket material to prevent flow of fluid through the body and/or over the surfaces.

- Shank

The portion of a bolt which lies under the head.

- Shear joint

A joint which is subjected primarily to loads acting more or less perpendicular to the axes of the bolts.

- Slug wrench

A box wrench with an anvil on the end of the handle. Torque is produced by striking the anvil with a sledge hammer. Called a flogging wrench in England.

- Spherical washer

A washer whose upper surface is semispherical. Used with a nut whose contact face is also semispherical. Reduces bending stress in a bolt or stud, by allowing some self-alignment and/or some compensation for nonparallel joint surfaces or Angularity.

- Spiral-wound gasket

A gasket design which is formed by winding spring-like material, usually “V” shaped, plus a suitable filler material, into a spiral.

- Spring constant

Equivalent to the “stiffness” of a bolt and defined as the initial preload divided by the elongation of the bolt after application of load.

- Standard deviation

A statistical term used to quantify the Scatter in a set of data points. If the standard deviation is small, most of the data points are “nearly equal.” A large deviation means less agreement.

- Stiffness

Ability of a body to resist deformation due to the action of external forces. Reciprocal of elasticity.

- Strain

Change in dimensions or shape of a body due to applied force or stress.

- Stress area

The effective cross-sectional area of the threaded section of a fastener. Used to compute average stress levels in that section. Based on the mean of pitch and minor diameters.

- Stress corrosion cracking (SCC)

A common form of Stress cracking in which an Electrolyte encourages the growth of a crack in a highly stressed bolt. Only a tiny quantity of electrolyte need be present, at the tip or face of the crack.

- Stress cracking

A family of failure modes, each of which involves high stress and chemical action. The family includes Hydrogen embrittlement, Stress corrosion cracking, stress embrittlement, and hydrogen-assisted stress corrosion.

- Stress factor

A calibration constant used in ultrasonic measurement of bolt stress or strain. It is the ratio between the change in ultrasonic transit time caused by the change in length of the fastener, under load, to the total change in transit time (which is also affected by a change in the stress level).

- Stress relaxation

Loss of stress at a constant gasket thickness as a function of time, after application of a specified compressive load at a specified rate, at constant temperature.

- Stud

A headless threaded fastener threaded on both ends, with an unthreaded body in the middle section, or threaded from end to end. Used with two nuts, or with one nut and a tapped hole.

- Surface roughness

Fine irregularities of the flange surface finish.

- Temperature factor

A calibration constant used in ultrasonic measurement of bolt stress or strain. Accounts for the effects of thermal expansion and the temperature-induced change in the velocity of sound.

- Tensile strength

Breaking tensile force divided by the original cross-sectional a

- Tension, bolt

Tension (tensile stress) created in the bolt by assembly preloads and/or such things as thermal expansion, service loads, etc.

- Tension joint

A joint which is primarily subjected to loads acting more or less parallel to the axes of the bolts.

- Tensioner

A hydraulic tool used to tighten a fastener by stretching it rather than by applying a substantial torque to the nut. After the tensioner has stretched the bolt or stud, the nut is run down against the joint with a modest torque, and the tensioner is disengaged from the fastener. The nut holds the stretch produced by the tensioner.

- Thread form

The cross-sectional shape of the threads, defining thread angle, root, and crest profiles, etc.

- Thread length

Length of that portion of the fastener which contains threads cut or rolled to full depth.

- Thread run-out

That portion of the threads which are not cut or rolled full depth, but which provide the transition between full-depth threads and the body or head. Officially called thread washout or vanish, although the term run-out is more popular. (Run-out is officially reserved for rotational eccentricity, as defined by total indicator reading or the like.)

- Threaded fastener

Studs, bolts, and screws of all sorts, with associated nuts.

- Tightness class

Maximum acceptable specific leakage rate for particular applications.

- Tightness parameter Tp

Mathematical relationship between the measured specific leakage rate and the internal fluid pressure causing it.

- Tongue and groove flange

A flange system in which one flange is provided with an annular tongue and the other with a complimentary groove to accept it.

- Torque

The twisting moment, product of force and wrench length, applied to a nut or bolt.

- Torque monitor

A torque tool control system which monitors the amount of torque being developed by the tool during use, but does not control the tool or the torque produced.

- Torque multiplier

A gearbox used to multiply the torque produced by a small hand wrench (usually a Torque wrench). The output of the multiplier drives the nut or bolt with a torque that is higher, and a speed that is lower, than input torque and speed. There is no torque gage or readout on the multiplier.

- Torque wrench

A manual wrench which incorporates a gage or measuring apparatus of some sort to measure and display the amount of torque being delivered to the nut or bolt. All wrenches produce torque. Only a torque wrench tells how much torque.

- Transducer

A device which converts one form of energy into another. An ultrasonic transducer, for example, converts electrical energy into acoustic energy (at ultrasonic frequencies) and vice versa.

- Turn-of-nut

Sometimes used to describe the general rotation of the nut (or bolt head) as the fastener is tightened. More often used to define a particular tightening procedure in which a fastener is first tightened with a preselected torque, and is then tightened further by giving the nut an additional, measured, turn such as “three flats” (180°).

- Ultimate strength

The maximum tensile strength a bolt or material can support prior to rupture. Always found the plastic region of the stress-strain or force-elongation curve, and so is not a design strength. Also called Tensile strength and ultimate tensile strength.

- Ultrasonic extensometer

An electronic instrument which measures the change in length of a fastener ultrasonically as, or before and after, the fastener is tightened.

- Width across flats

A principal dimension of nuts or of bolt heads.

- Work hardening

The slight increase in hardness and strength produced when a body is loaded past its yield point. Also called strain hardening.

- Yield strength

That stress level which will create a permanent deformation of 0.2% or 0.5% or some other small, preselected, amount in a body. Approximately equal to the elastic and proportional limits of the material, a little higher than the proof strength of a bolt.