BLOG

THE NEXT GENERATION IN EXTREME TEMPERATURE SEALING

THE NEXT GENERATION IN EXTREME TEMPERATURE SEALING

<<INNOVATION BY LEADER GASKET NOW BAM APPROVED FOR OXYGEN SERVICE>>

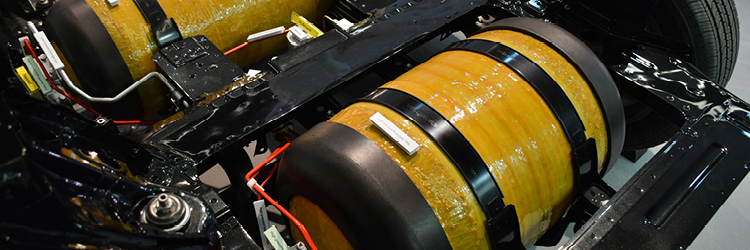

Leader Gasket’s newest innovation on extreme temperature solutions has received great interest in several markets!

LeaderTHERM

NXT is a modified phlogopite base material designed for critical

high-temperature services such as turbochargers, catalytic cracking

systems, power generation, gas boilers and equipment, and NOx containing

applications.

Due to the very low weight loss at high

temperatures (up to 1000°C/1832°F) of the modified phlogopite base

material, LeaderTHERM NXT offers not only being extremely temperature

resistant but also exhibit very low leakage in combination with

practically no loss of gasket seating stress.

LeaderTHERM NXT

exceeds in performance compared to other high-temperature materials in a

thermal cycling leakage test. Data studies are available upon request

exhibiting LeaderTHERM NXT sealing superiority.

Phlogopite is an

important and relatively common end-member composition of biotite.

Phlogopite micas are found primarily in igneous rocks, although it is

also common in contact metamorphic aureoles of intrusive igneous rocks

with magnesian country rocks and in marble formed from impure dolomite.

LeaderTHERM NXT also is an ideal alternative for graphite gaskets that are attacked by oxidation (>1000°C/1832°F).

TESTED AND PROVEN

BAM APPROVAL OXYGEN SERVICE AT HIGHEST TEST CONDITIONS

TA LUFT CERTIFICATION

Both LeaderTHERM NXT style 1000 Spiral Wound and style 1010 Kammprofile version are compliant with tightness criteria according TA Luft [10-4 mbar . l/(m . s)] as per Guideline VDI 2440 (Nov. 2000) and 2200 (June 2007) with rated high-grade srsling system for the purposes of TA Luft.

LEADERTHERM NXT IS AVAILABLE IN THE FOLLOWING STYLES

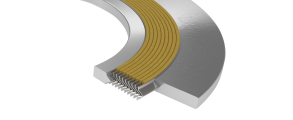

LeaderTHERM NXT 1000 filler for Leader SR/SRI Spiral Wound Gasket

LeaderTHERM NXT 1010 facing material for LeaderKAM kammprofile gasket

LeaderTHERM 1020 reinforced gasket sheet

SEALING CHARACTERISTICS

■■ Extreme temperature gasket material

■■ Effective tightness even at high-temperatures (up to 1000°C/1832°F) and pressures

■■ Low weight loss in extreme conditions

■■ Oxidation resistant

■■ Sustainable solution that uses organic ingredients

■■ Outstanding chemical resistance

■■ Non-ageing

Can we help you?

Ask us a question

Info@leadergt.com

Phone: 1-281-542-0600